Charcoal burning

Charcoal is the blackish residue consisting of impure carbon obtained by removing water and other volatile constituents from animal and vegetation substances. Charcoal is usually produced by heating wood, sugar, bone char, or others substances in the absence of oxygen (see char). The soft, brittle, lightweight, black, porous material resembles coal and is 85% to 98% carbon with the remainder consisting of volatile chemicals and ash.

The first part of the word is of obscure origin, but the first use of the term "coal" in English was as a reference to charcoal. In this compound term, the prefix "chare-" meant "turn," with the literal meaning being "to turn to coal." The independent use of "char," meaning to scorch, to reduce to carbon, is comparatively recent and must be a back-formation from the earlier charcoal. It may be a use of the word charren or churn, meaning to turn, i.e. wood changed or turned to coal, or it may be from the French

charbon. A person who manufactured charcoal was formerly known as a collier, though the term was used later for those who dealt in coal, and the ships that transported it.

Wood pile before covering it by turf or soil, and firing it (around 1890)

An abandoned charcoal kiln near Walker, Arizona.

Modern charcoal retorts

Production of wood charcoal in districts where there is an abundance of wood dates back to a very remote period, and generally consists of piling billets of wood on their ends so as to form a conical pile, openings being left at the bottom to admit air, with a central shaft to serve as a flue. The whole pile is covered with turf or moistened clay. The firing is begun at the bottom of the flue, and gradually spreads outwards and upwards. The success of the operation depends upon the rate of the combustion. Under average conditions, 100 parts of wood yield about 60 parts by volume, or 25 parts by weight, of charcoal; small scale production on the spot often yields only about 50%, large scale was efficient to about 90% even by the 17th century. The operation is so delicate that it was generally left to professional charcoal burners. These often worked in solitary groups in the woods and had a rather bad social reputation, especially traveling ones who often sold a sack (priced at about a day's wage) with lots of rubbish mixed in to farmers and townsfolk.

Historically the massive production of charcoal (at its height employing hundreds of thousands, mainly in Alpine and neighbouring forests) has been a major cause of deforestation, especially in Central Europe. In England, many woods were managed as coppices, which were cut and regrew cyclically, so that a steady supply of charcoal would be available (in principle) forever; complaints (as early as in Stuart England) about shortages may relate to the results of temporary over-exploitation or the impossibility of increasing production. The increasing scarcity of easily harvested wood was a major factor for the switch to the fossil fuel equivalents, mainly coal and brown coal for industrial use.

The modern process of carbonizing wood, either in small pieces or as sawdust in cast iron

retorts, is extensively practiced where wood is scarce, and also by reason of the recovery of valuable byproducts (wood spirit, pyroligneous acid, wood tar), which the process permits. The question of the temperature of the carbonization is important; according to J. Percy, wood becomes brown at 220°C, a deep brown-black after some time at 280°, and an easily powdered mass at 310°.[citation needed] Charcoal made at 300° is brown, soft and friable, and readily inflames at 380°; made at higher temperatures it is hard and brittle, and does not fire until heated to about 700°.

In Finland and Scandinavia, the charcoal was considered the by-product of wood tar production. The best tar came from pine, thus pinewoods were cut down for tar

pyrolysis. The residual charcoal was widely used as substitute for metallurgical

coke on blast furnaces for smelting. Tar production led to rapid deforestation: it has been estimated all Finnish forests are younger than 300 years by their age. The end of tar production in the end of the 19th century meant also rapid re-forestation.

One of the most important historical applications of wood charcoal was as a constituent of gunpowder. It was also used in metallurgical operations as a reducing agent, but its application has been diminished by the introduction of coke, anthracite smalls, etc. A limited quantity is made up into the form of drawing crayons; but the greatest amount is used as a fuel, which burns hotter and cleaner than wood. Charcoal is often used by blacksmiths, for cooking, and for other industrial applications.

A charcoal powered bus being "fired up" in post war Japan (late 1940's)

Historically, charcoal was used in great quantities for smelting iron in bloomeries and later blast furnaces and finery forges. This was replaced for this by coke during the Industrial Revolution. For this purpose, charcoal in England was measured in dozens (or loads) consisting of 12 sacks or shems or seams, each of 8 bushels.

Commercially, charcoal is often found in either lump, briquette or extruded forms:

- Lump charcoal is made directly from hardwood material and usually produces far less ash than briquettes.

- While some briquettes are made from a combination of charcoal (heat source), brown coal (heat source), mineral carbon (heat source), borax, sodium nitrate (ignition aid), limestone (uniform visual ashing), starch (binder), raw sawdust (ignition aid) and possibly additives like paraffin or lighter fluid to aid in lighting them, other "natural" briquettes are made solely from charcoal and a binder. The charcoal briquette was first invented by Henry Ford from wood and sawdust scraps from his automotive plant.[1]

- Extruded charcoal is made by extruding either raw ground wood or carbonized wood into logs without the use of a binder. The heat and pressure of the extruding process hold the charcoal together. If the extrusion is made from raw wood material, the extruded logs are then subsequently carbonized.

The characteristics of charcoal products (lump, briquette or extruded forms) vary widely from product to product. Thus it is a common misconception to stereotype any kind of charcoal, saying which burns hotter, etc.

Charcoal is sometimes used to power commercial road vehicles, usually buses - in countries where oil is scarce or completely unavailable. In the years immediately after the second world war, charcoal buses were in regular use in Japan and are still used today in North Korea. [1]

The porosity of activated charcoal accounts for its ability to readily adsorb gases and liquids; charcoal is often used to filter water or adsorb odors. Its pharmacological action depends on the same property; it adsorbs the gases of the stomach and intestines, and also liquids and solids (hence its use in the treatment of certain poisonings). Charcoal filters are used in some types of gas mask to remove poisonous gases from inhaled air. Wood charcoal also to some extent removes coloring material from solutions, but animal charcoal is generally more effective.

Animal charcoal or bone black is the carbonaceous residue obtained by the dry distillation of bones; it contains only about 10% carbon, the remainder being calcium and magnesium phosphates (80%) and other inorganic material originally present in the bones. It is generally manufactured from the residues obtained in the glue and gelatin industries. Its decolorizing power was applied in 1812 by Derosne to the clarification of the syrups obtained in sugar refining; but its use in this direction has now greatly diminished, owing to the introduction of more active and easily managed reagents. It is still used to some extent in laboratory practice. The decolorizing power is not permanent, becoming lost after using for some time; it may be revived, however, by washing and reheating.

Four sticks of vine charcoal and four sticks of compressed charcoal.

Charcoal is used in art for drawing, making rough sketches in painting, and is one of the possible media for making a parsemage. It must usually be preserved by the application of a fixative. Artists generally utilize charcoal in three forms:

- Vine charcoal is created by burning sticks of wood (usually willow or linden/Tilia) into soft, medium, and hard consistencies. Bamboo charcoal is the principal tool in Japanese Sumi-e (炭絵 lit: charcoal drawing) art.

- Compressed charcoal charcoal powder mixed with gum binder compressed into round or square sticks. The amount of binder determines the hardness of the stick. Compressed charcoal is used in charcoal pencils.

- Powdered charcoal is often used to "tone" or cover large sections of a drawing surface. Drawing over the toned areas will darken it further, but the artist can also lighten (or completely erase) within the toned area to create lighter tones.

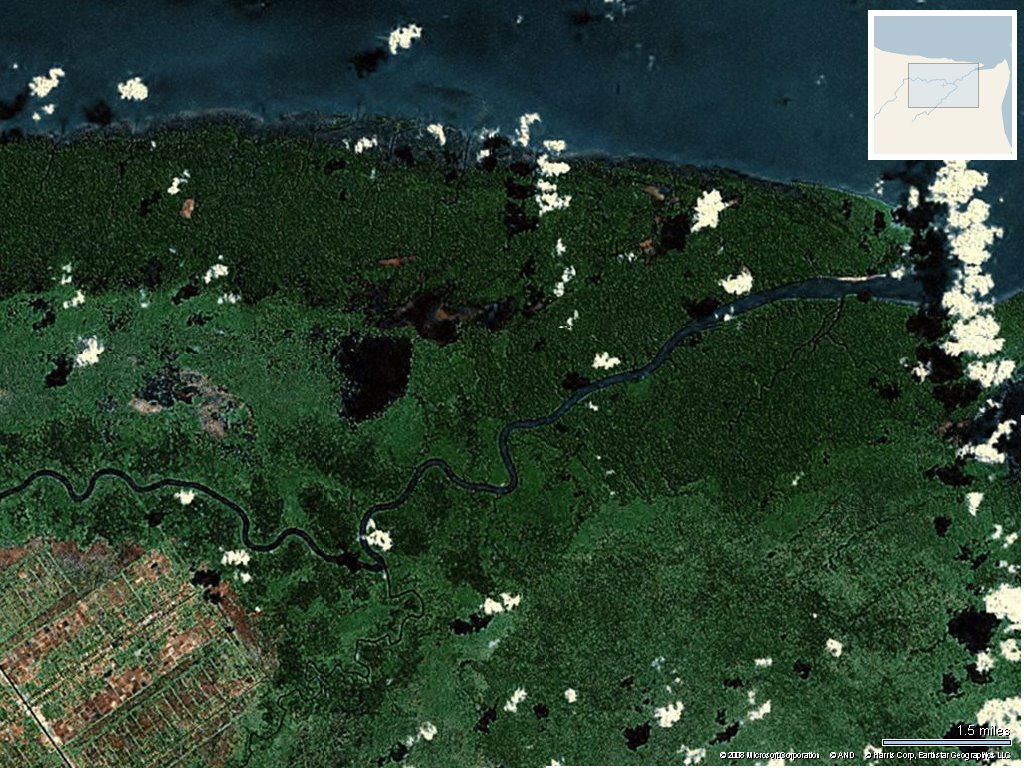

One additional use of charcoal rediscovered recently is in horticulture. Although American

gardeners have been using charcoal for a short while, research on Terra preta

soils in the Amazon has found the widespread use of biochar by pre-Columbian natives to turn otherwise unproductive soil into very rich soil. The technique may find modern application, both to improve soils and as a means of carbon sequestration.

Sources, references and external links

- Ignite Products - New generation charcoal products.

- Barbecue Charcoal - The available choices for the backyard barbecue

- Natural History of Europe - 2005 TV co-production including BBC and ZDF

- On Charcoal

- The Valley - BBC TV - one year of life on a 17th century farm reenacted by archaeologists and historians

- The Lump Charcoal Database - Information about lump charcoal.

- H E Z Organisation - Information about charcoal in Germany.

- How charcoal briquettes are made.

- [2] - Information about charcoal.

- Photo of traditional charcoal production A forest kiln

- [3] - Charcoal making community for livelihood

- [4] - Traditional charcoal production method, India

- The River Wey and Wey Navigations Community Site — a non-commercial site of over 200,000 words all about the Wey Valley and includes a photo file on charcoal production and information relating to gunpowder manufacture at Chilworth.

- [5]

Catoctin Mountain Park, Maryland, USA, includes interpretive features ("Charcoal Trail", etc) on the history of charcoal making in the area. - Bamboo Charcoal - Properties and Facts

- Coconut Charcoal - Facts

- Simple Home Charcoal Process

1 komentar:

The Rest of the Biochar Story:

Charles Mann ("1491")in the Sept. National Geographic has a wonderful soils article which places Terra Preta / Biochar soils center stage.

I think Biochar has climbed the pinnacle, the Combined English and other language circulation of NGM is nearly nine million monthly with more than fifty million readers monthly!

We need to encourage more coverage now, to ride Mann's coattails to public critical mass.

Please put this (soil) bug in your colleague's ears. These issues need to gain traction among all the various disciplines who have an iron in this fire.

http://ngm.nationalgeographic.com/2008/09/soil/mann-text

I love the "MEGO" factor theme Mann built the story around. Lord... how I KNOW that reaction.

I like his characterization concerning the pot shards found in Terra Preta soils;

so filled with pottery - "It was as if the river's first inhabitants had

thrown a huge, rowdy frat party, smashing every plate in sight, then

buried the evidence."

A couple of researchers I was not aware of were quoted, and I'll be sending them posts about our Biochar group: http://tech.groups.yahoo.com/group/b...guid=122501696

and data base;

http://terrapreta.bioenergylists.org/?q=node

I also have been trying to convince Michael Pollan ( NYT Food Columnist, Author ) to do a follow up story, with pleading emails to him

Since the NGM cover reads "WHERE FOOD BEGINS" , I thought this would be right down his alley and focus more attention on Mann's work.

I've admiried his ability since "Botany of Desire" to over come the "MEGO" factor (My Eyes Glaze Over) and make food & agriculture into page turners.

It's what Mann hasn't covered that I thought should interest any writer as a follow up article.

The Biochar provisions by Sen.Ken Salazar in the 07 farm bill,

Dr, James Hansen's Global warming solutions paper and letter to the G-8 conference last month, and coming article in Science,

http://arxiv.org/ftp/arxiv/papers/0804/0804.1126.pdf

The many new university programs & field studies, in temperate soils

Glomalin's role in soil tilth & Terra Preta,

The International Biochar Initiative Conference Sept 8 in New Castle;

http://www.biochar-international.org/ibi2008conference/aboutibi2008conference.html

Given the current "Crisis" atmosphere concerning energy, soil sustainability, food vs. Biofuels, and Climate Change what other subject addresses them all?

Biochar, the modern version of an ancient Amazonian agricultural practice called Terra Preta (black earth), is gaining widespread credibility as a way to address world hunger, climate change, rural poverty, deforestation, and energy shortages… SIMULTANEOUSLY!

This technology represents the most comprehensive, low cost, and productive approach to long term stewardship and sustainability.

Terra Preta Soils a process for Carbon Negative Bio fuels, massive Carbon sequestration,10X Lower Methane & N2O soil emissions, and 3X Fertility Too. Every 1 ton of Biomass yields 1/3 ton Charcoal for soil Sequestration.

Carbon to the Soil, the only ubiquitous and economic place to put it.

Erich

Posting Komentar